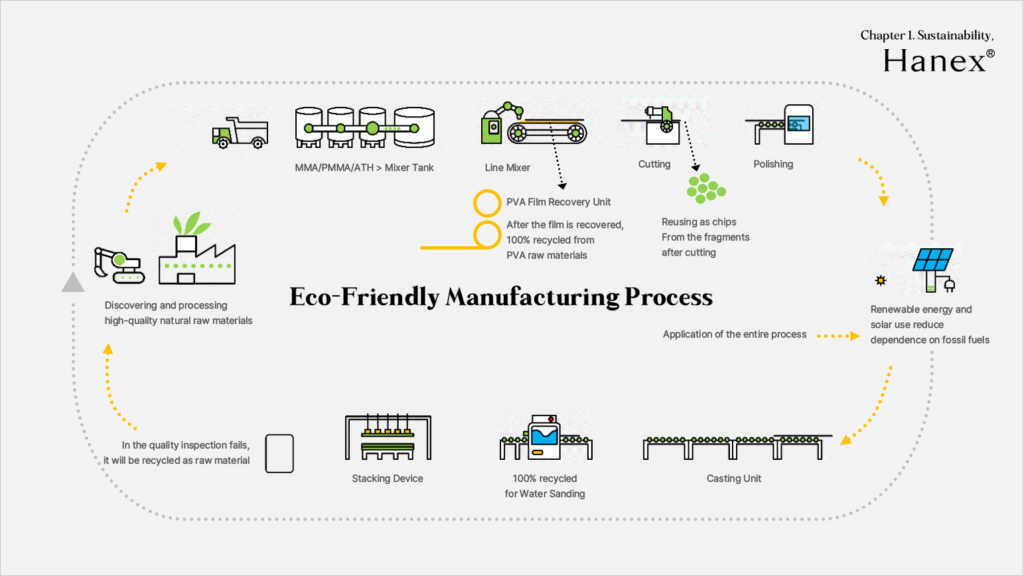

In today’s design landscape, sustainability is not just a passing phase; it’s an essential factor to consider. As we aim to create spaces that are both visually appealing and environmentally conscious, Hanex Solid Surfaces by Hyundai L&C USA stands out for its dedication to eco-friendly production methods.

Optimizing Production Processes to Reduce Waste to a Minimum

Hanex places an emphasis on sustainability throughout its production process by implementing eco-friendly manufacturing methods that aim to minimize waste and optimize material usage efficiently. They ensure that all components of the materials are utilized fully to significantly reduce waste generation. Through the adoption of 100% water-based procedures, Hanex successfully limits the emission of volatile organic compounds (VOCs), resulting in safer products for individuals and the environment.

Best Practices in Strategic Transportation

Hanex’s sustainability initiatives also focus on transportation efficiency by positioning production stages close to one another to minimize energy consumption and greenhouse gas emissions from long-distance transport. Their strategic logistics planning not only reduces their carbon footprint but also enhances the efficiency of their supply chain operations.

Embracing a Comprehensive Dedication to Environmental Sustainability

Hanex demonstrates its commitment to eco-friendliness through the choice of materials and production techniques employed in its operations. They consistently strive to improve their sustainability efforts to ensure that their offerings are not only visually appealing but also promote environmental conservation for future generations.

Let’s come together to support an eco-friendly approach to interior design and make decisions that not only enhance our surroundings but also support our planet’s well-being, all while keeping beautiful spaces in mind.

View the full Hanex Solid Surface collection from SolidSurface.com

To learn more about Hanex and their commitment to sustainability, visit Hanex Solid Surfaces: Where Sustainability Meets Eco-Friendliness.