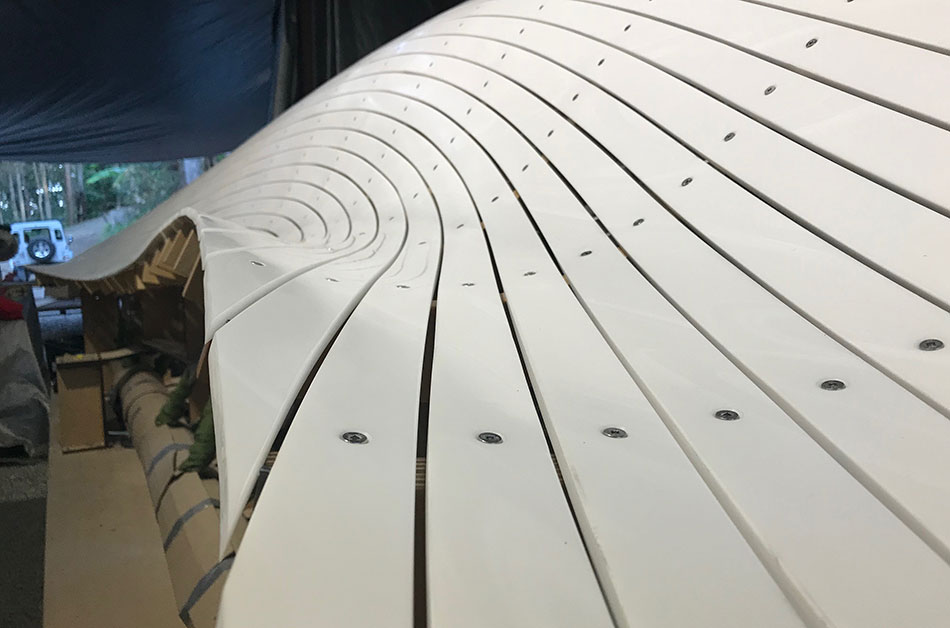

Beautifully backlit solid surface kitchen countertop using Light Tape®, Cat Eye from STUDIO Collection®

Using Cat Eye from the STUDIO Collection® and Light Tape®, Jerry Michaels (the idea man) and Jim Glinski (craftsman and author) create an incredibly unique solid surface kitchen countertop.

Here at SolidSurface.com we enjoy getting to know our customers. It’s always interesting to learn their background, hear their ideas for the solid surface sheet material they purchase, and then see their projects come to life. We had an opportunity to talk with one such customer, Jerry Michaels, and his craftsman, Jim Glinski, about their DIY project and how it turned out.

The Backlit Countertop

Jerry Michaels first came to us with an interesting project in mind for his kitchen remodel. He discovered a product online called Vitrazzo, which is a countertop product made of recycled glass. He found pictures of their product done with backlighting and knew he just had to have a countertop like that. What he also discovered was that the cost was way too expensive. He then set out exploring what other materials Continue reading