Countertops made of solid surface material (i.e., Corian® or HI-MACS®) are an excellent choice and an easy addition to the cabinetmaker’s specialty line. Cabinetmakers are already extremely skilled and detail-oriented in their ability to create cabinetry for any room type using a variety of materials. Yet many may not realize just how easy it is to add a solid surface countertop to a newly constructed cabinet. Doing this adds value to their products, and service to customers, not to mention extra income for the business. Why outsource that extra step, when one already has the skills and tools necessary to easily complete the project?

For those cabinetmakers already offering granite, quartz or other types of stone countertops, consider giving customers another, and possibly more cost effective, choice in countertop material.

Cabinetmakers Already Have the Tools and Skills Needed

Almost all cabinet shops already have the tools necessary to complete a large percentage of all types of solid surface material fabrication projects. Those tools include:

- 2-3 horsepower ½” shank router

- 5” or 6” random orbit sander

- skill saw, or precision track saw

- jig saw

- drill

- bar clamps

- spring clamps

- adhesive dispensing gun (not generally available)

- tape measure

The Resources section of SolidSurface.com discusses the steps, and tips and tricks, for building solid surface countertops. It is a great place to find out more information on things like why mirror cuts are important, using solid surface glue correctly, or how to thermoform solid surface.

Why Choose Solid Surface for Countertops

As stated above, cabinetmakers already have the skills and resources available to them to add countertops to their wood cabinets. With a bit of education, it is easy to see why a solid surface countertop is a superb option, and the most trouble-free choice, to complement and finish a cabinet.

Solid surface (best known as Corian®) is made of acrylic resin combined with filler, acrylic chips and color pigments. The composition is then poured or extruded as a ½” (or ¼”) thick sheet that is typically 30” x 144.” It is the same color throughout its thickness. Solid surface can be readily cut, routed and sanded just like wood for countertops, shower walls, external cladding for buildings, signage and furniture, or wherever non-porosity and infrequent maintenance are highly valued.

Moreover, it can be thermoformed into curved shapes and printed on using dye-sublimation techniques that deposit ink below the surface so the image is permanent. The technique involves heating the solid surface and then transferring the ink to the surface under a vacuum condition. The images and text are then captured in the pores of the solid surface. It can then be thermoformed, fabricated, and cleaned or sanded lightly. Clearly, a very versatile material.

Outstanding Qualities and Durability

Not only is solid surface easy to work with, especially for a cabinetmaker, it has other outstanding qualities and characteristics that make it a top choice for countertops (see Comparison Chart of popular countertop surfacing materials):

- Easily renewable – solid surface material is easily renewable even after many years of usage. Scrubbing with a Scotch-Brite™ pad or sanding the surface is all that is required to refresh the surface. Compare that to other materials such as granite, marble or quartz, and even wood, which requires sanding (or stripping) and painting or staining.

- Impervious to liquids and harsh chemicals – solid surface does not absorb water or moisture which eliminates swelling and shrinking during humid or dry seasons. It is also resistant to many of the harsh chemicals used in households.

- Antimicrobial – safe for use in residential and commercial applications because it is nonporous, antimicrobial and will not support the growth of bacteria. It is invaluable in commercial bathrooms and healthcare facilities like hospitals, doctors’ offices, gyms, hospices, and retirement homes.

- Invisible seams – the seam virtually disappears and does not show when two pieces of solid surface are seamed together properly using matching adhesive. This means that when mistakes are made, the material can be glued back together and the seam is undetectable to the untrained eye. However, it should be noted that the invisible nature of the seams may not apply to solid surface sheets with veined or wavy patterns.

- More stable than wood – solid surface is very stable when compared to wood, with no shrinkage, cracks or raised grain. It is the ideal material to complement a beautifully crafted wood cabinet. Although solid surface can slightly expand and contract from temperature changes, it does not crack or absorb moisture and has no grain to contend with.

- NSF/ANSI Standard 51 food handling safety certification – virtually all brands of solid surface carry the NSF/ANSI Standard 51 certification. This means the material is safe for all types of food handling, serving and preparation in both residential and commercial applications. It is an excellent choice for kitchen countertops, restaurants, schools, and other food preparation facilities.

- ECO friendly – many solid surface brands contain recycled materials qualifying for Leeds points when those products are part of a project that is striving for ECO friendliness.

- UV/weather resistant – the lighter colors of solid surface are excellent for outdoor use. They show very little weather or UV impact even after many years. Solid surface material can withstand humidity, dry air, as well as freezing and hot weather conditions. Signs, outdoor benches, BBQ work surfaces and cladding for buildings are among its many uses. Even graffiti can be easily removed without changing the appearance of the surface. Over extended years, the more saturated and darker colors may show a white haze that can be washed or sanded away.

Brands of Solid Surface

There are many manufacturers of solid surface offering hundreds of colors, patterns and designs that will please even the most discriminating of customers. The leading and most well known brand of solid surface is Corian®, by DuPont. However, cabinetmakers can benefit from a cost standpoint to look at other brands, or less-than-full-sheet sizes. Below is a list of other brands and their manufacturers::

- Affinity™ Surfaces (Domain™ Industries)

- Avonite Surfaces® (Aristech® Surfaces)

- Formica® Solid Surfacing (Formica)

- Hanex Solid Surfaces (Hyundai L&C USA LLC)

- HI-MACS® (LG Hausys)

- Livingstone® (US Surfaces)

- Meganite®

- Mystera® Solid Surface

- Select Grade (Solidsurface.com)

- Staron® Solid Surfaces (LOTTE Advanced Materials)

- STUDIO Collection® (Aristech® Surfaces)

- Wilsonart® (Wilsonart® Engineered Surfaces)

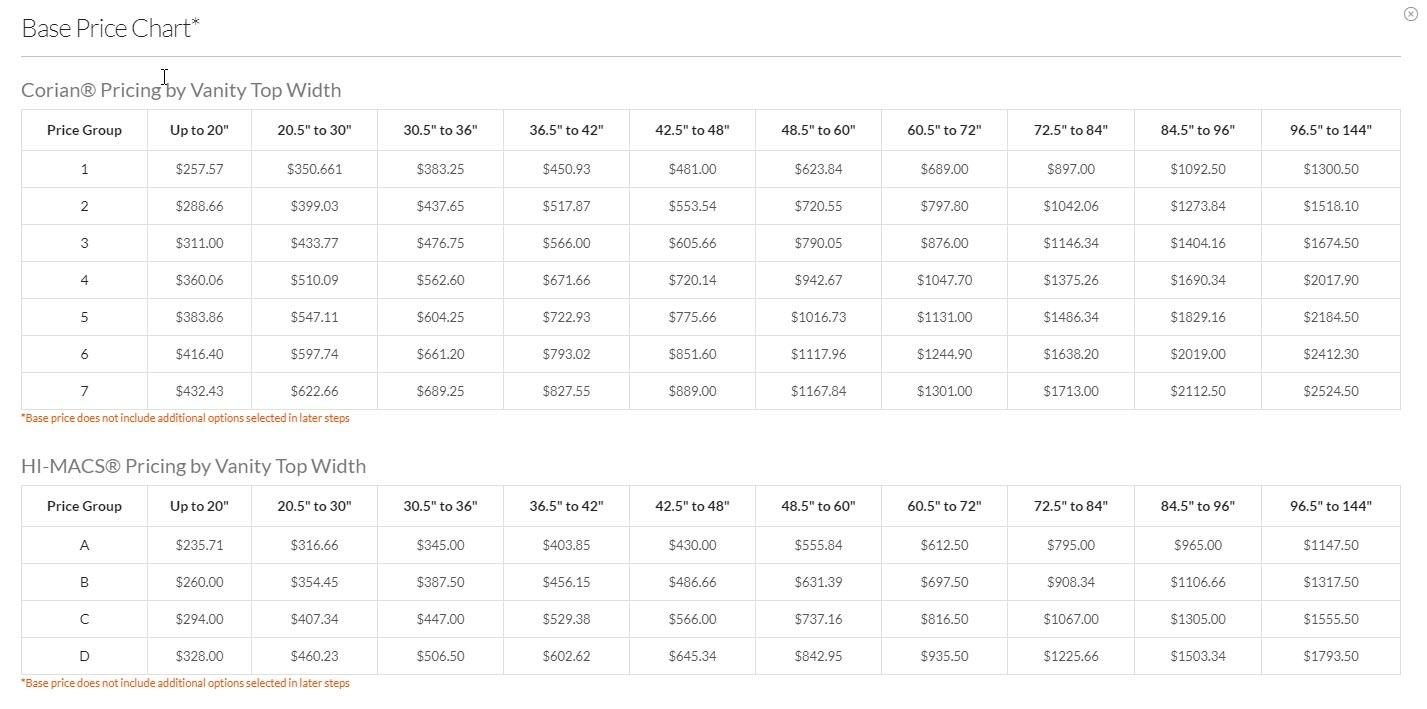

Typically, each of the manufacturers categorize the colors into price groups ranging from low to high. The manufacturers also offer similar colors and patterns to one another so it pays to compare across the brands.

Colors, Patterns and Designs

With so many colors, patterns and designs of solid surface to choose from, it helps to narrow things down. The latest technology enables solid surface colors to mimic marble, quartz, concrete, granite and even wood. It is easiest to start by having the customer choose a color family, i.e., white or gray, and then choose from solid or patterned solid surface colors.

White Solid Surface Colors

While it may seem simple to choose a white solid surface countertop material, just like choosing paint, there are many different “whites” to choose from. Because of this, a cabinetmaker could consider offering three of the most popular white solid surface color choices, perhaps a warm, a cool, and a neutral.

Patterned Solid Surface Material

Patterns in solid surface colors refer to the amount of particulate and size of particulate embedded in the sheet material. Sand is the smallest and then small, medium, and large particulates. Marbling or veined patterned material is very popular because it mimics the look of marble, yet solid surface has a warm touch and feel to it. Much like wood, solid surface provides a forgiving hardness. (For example, when a glass is tipped over on a solid surface countertop, it may bounce a bit, but likely won’t break.) Select Grade, which matches the colors of Corian®, is one of SolidSurface.com’s most popular and least expensive brands with veining. While veined patterns are very beautiful, note they are a bit trickier to work with when it comes to seaming large-area countertop projects.

Solid Surface “Wood Grain” Look

It has been a while since a major manufacturer has provided a wood grain pattern in solid surface. Corian® Design recently introduced the Nuwood collection in two colors, Mahogany and Beech. The three images below demonstrate several of the amazing qualities of the solid surface mahogany look-alike. The airport reception area desk and lounge benches depicted are thermoformed into curvatures with a seamless look. The fact that the solid surface material is used in an airport is a testament to how it is expected to withstand constant and heavy use.

The third image is a vanity top demonstrating the waterproof nature of solid surface. Here, the sink is built from solid surface.

Translucent Options

For those who love crafting a piece with that little extra something in it, there are solid surface brands that offer translucent colors ideal for backlighting. STUDIO Collection® from Aristech® Surfaces takes it to the next level with an entire translucent collection. These colors are stunning in and of themselves, yet have an even more dramatic effect when backlit.

Right-sizing with Extra Wide Solid Surface Sheet Material

As with any cabinet design, determining the amount of material needed is important for staying within the budget of the project. The same is true with solid surface countertops. There are ways to save on the costs of the project by first determining whether full sheets, partial sheets or a combination are needed. Another way to save on the cost is by choosing from overstock material versus in-production material.

Avonite Surfaces®, from Aristech®, is now available in a variety of extra wide sheets up to 60” wide and 144” long. There are major advantages to having the extra wide sheets: it eliminates seaming smaller pieces together and may eliminate other steps that accompany using narrower sheets. For example, it would not be necessary to add backing plates behind the seam, cut grooves for the backing plates, or utilize batten strips to hide the seam. Additionally, custom colors are available in Avonite Surfaces® in very low minimum order quantities, so it is less expensive to order for a smaller project.

Cabinets Made of Corian® Solid Surface

While solid surface is widely known as countertop material, it also works extremely well as a cabinet material. Cabinets made of Corian®, or any other brand of solid surface, can last forever and will not require a lot of maintenance.

Just like countertops, cabinets made of solid surface material will share the same great characteristics:

- waterproof;

- will not support the growth of germs and bacteria;

- easy to clean;

- resurfaceable with Scotch-Brite® or by sanding;

- have no grain to contend with like wood;

- expansion/contraction is minimal;

- no finishing paint, varnish or oil is needed.

There is a growing demand for cabinets made of solid surface. The healthcare industry, i.e., hospitals, were one of the first to recognize the benefits of using solid surface material. The hospitality industry, i.e., hotels and restaurants, is also more widely using solid surface material for countertops and cabinets.

As an example, a hospital outfits a patient room with solid surface cabinets and countertops even though they cost more initially. The cabinets and tops have essentially no place for germs and other pathogens to hide and can be wiped or sprayed with harsh bactericides without concern for damage. Over the years of use, the cabinets and counters may become dirty, dingy, marked or scratched by everyday use. The dirt and scratches can be easily removed with Scotch-Brite® or sandpaper, returning the cabinet to like-new condition. No need for paint or varnish. These cost-saving measures can be sufficient enough to offset the initial cost and reduce the use of new resources even if replacement was necessary.

The Easy Finish

It is much easier to put the finishing touches on solid surface than wood. While solid surface does require a finish, how much sanding depends on whether the customer specs require a matte or high gloss surface. However, solid surface requires no wax or liquid finish such as paint or varnish, so once the sanding is complete, you are finished!

Finding Solid Surface Material

SolidSurface.com carries most brands of solid surface in all varieties of colors and patterns. Cabinetmakers can find an abundance of sizes, ranging from a Premium full sheet down to a remnant small tabletop size, and more. Save money in the Overstock section, or visit the Sales section of the website for the best deals and pricing.

Cabinetmakers can also explore the Custom Vanity Top Designer℠ option to order a custom-sized solid surface countertop with or without sink and faucet holes. Countertops designed in this program can be delivered within 15 business days of placing the order.

Once a sheet order is placed, shipping is typically within 10 business days. Orders can be shipped anywhere within the continental USA. The Sales Support Team is standing by to answer any questions or to lend assistance in placing an order – 888-715-3007.