Recently announced–the Grand Prize Winners of the 2018 Corian® Design Awards for Outstanding Design: Furling, designed by davisthomas; and Tweed Terrace House, designed by Raunik Design Group. Each year since 2006, CASF Australia, a national distributor of Corian® solid surface, provides the platform for the design awards that recognize local designers in their field of expertise for their creative use of Corian® solid surface.

Two winners are selected at the end of each quarter (March, June, September and December) from two categories, Residential and Commercial. Then, the winner from each category is placed in the pool of candidates from the entire year. After that, the overall winners are selected from there.

The 2018 Corian® Design Awards Grand Prize Winners were chosen based on their exceptional ingenuity and astounding creativity, the type of talent for which the Australian design community is known. The Award recognizes innovators of the uses for Corian® and their abilities to transform ideas into projects previously thought to be unachievable.

The Furling Project

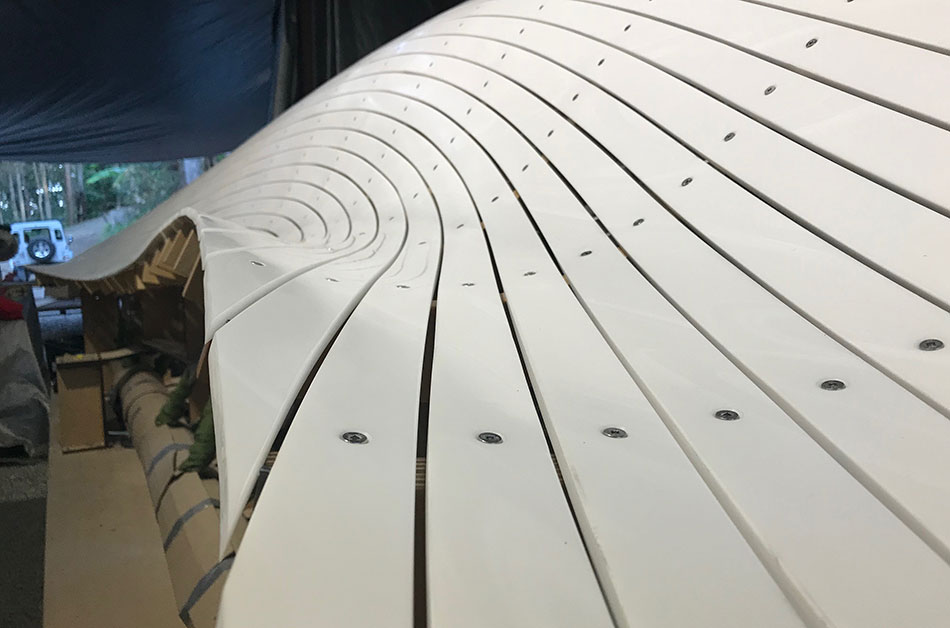

The winner of the Commercial category is Furling. Furling is a large-scale sculpture designed by davisthomas, artists who specialize in sculptural, installation-based projects for public spaces. Intertwining historical, current social, environmental and physical elements into their discovery process, the project was inspired by the nautical history of the wharf in the Brisbane river and Mary Street area. Consequently, davisthomas chose Corian® solid surface in Venaro White as their material. Corian® offered the creative opportunity davisthomas was seeking, coupled with its ability to move beyond everyday purpose, thereby making the sculpture robust and maintenance-free.

The Furling project was davisthomas’ first experience with Corian®. In particular, they were impressed with its responsiveness and fluidity. Additionally, they were pleased with the ease of fixing, seaming and finishing the material.

From the Designer

“Corian® made this project possible. The flexibility of the material’s thermoforming capabilities combined with the near seamless bonding capability of the joint adhesive allowed us to produce 9m linear planks that flow and glide up the side of the wall. Creating a majestic, dynamic sculptural artwork with a high quality finish.”

– Lubi Thomas and Adrian Davis

From the Judges

“This is a highly skilled and innovative implementation of Corian® to create a striking sculptural element.”

– Alexander Lotersztain

More on Furling

The Tweed Terrace Project

The winner of the Residential category is Tweed Terrace, a luxury home at Duranbah on the Gold Coast. Originally, the idea was envisioned by Mexican architect Javier Senosiain, then subsequently brought to fruition by Raunik Design Group. The organic design uses curves, thereby mimicking the ebb and flow of the sea, as opposed to angles–a sharp and complimentary contrast to the surrounding high-rises.

The smooth, curved design continues throughout the interior of the home, with custom finishes and a futuristic flare in woodworking craftsmanship. Careful color selections were made to suit the purposes of the rooms. Corian® Glacier White in matte finish was used for the bed surround. The vanity tops, with integrated basins, were done in Antarctica with a gloss finish.

From the Designer

“We wanted a product that looks like it flows with the curved walls and emerges from the wall. We wanted it to have its own form and dissipate in its own way.”

– Scott Bowden, Project Leader, Raunik Design Group

From the Judges

“Language of organic forms created by Corian® creates futuristic simplicity and fluidity throughout the entire house. Shows the versatility of the product.”

– Megan Smith

More on Tweed Terrace

The 2018 Grand Prize Winners of the Corian® Design Awards will be sent to Japan for a tour of the Corian® production facility. All finalists receive global and editorial exposure through the DuPont™ Network. Corian® Design Awards for 2019 is now open to all specifiers, architects/designers and students. In addition, shop fitters and Corian® fabricators may also enter on behalf of a designer.