Feeling overwhelmed by all of the sink options available? Well, it’s time to take a deep breath and relax. We’re here to help you focus your decision and hone in on the sink material and style that will fit your needs best for your Corian® or other brand of solid surface countertop.

To start, take a moment to consider what’s most important to you with regard to the new sink you are going to install in conjunction with your solid surface countertops. Where is your sink going to be placed—in a kitchen, bathroom, wet bar, laundry or even laboratory? Is your decision driven by design and aesthetics? Is it based on the fact that you want a new sink that is going to be durable and stand the test of time? Or perhaps an antiseptic environment and ease of cleaning are your prime outcomes?

It’s important to focus on what benefits are most important to you and what takes priority as you design your parameters.

We’ve identified three key considerations when choosing your new sink: the type of sink, whether or not to top mount or undermount it, and if undermounting it, whether or not to do a seamless undermount.

Time to pick your basin!

Type of Sinks Available

There are currently four types of materials that sinks are constructed from: solid surface, stainless steel, granite or quartz composite and cast iron. Pros and cons arise with each option available, such as cost, durability, aesthetics and antiseptic properties. Consider the pros and cons of each type.

Solid Surface (Acrylic) Sinks

Solid surface sinks offer a wide range of benefits. According to the U.S. Department of Commerce (2000), they (along with other composite sinks) are rising in popularity and use. They are molded from an acrylic resin with added fillers and colors and are the same color throughout. Because of this, any chips or scratches can be sanded out without causing any permanent damage or marks. Similarly, although solid surface sinks can discolor after extended use, this discoloration can be easily removed by scouring the basin with a cleanser, like Comet.

From a décor standpoint, standard solid surface sinks are currently offered in a handful of colors, like white, off-white and bone, to name a few. If color is a factor in your sink choice, then you might consider quartz. For the more design-adventurous, solid surface sink basins can also be creatively developed through thermoforming at the manufacturer.

Solid surface sinks, undermounted to your solid surface countertop using a seamless undermount approach (see below), are one of the most hygienic sink options available; meeting NSF 51 food equipment sanitation certification standard for “Splash Zone” and “Food Zone” applications. While this approach is not technically “seamless”, it is a bonding process that causes the two surfaces to come together so there is no support for the growth of bacteria and mold and no water penetration.

Lastly, if high heat is a factor in your sink usage, you might want to consider a stainless steel or cast iron option.

Granite or Quartz Composite Sinks

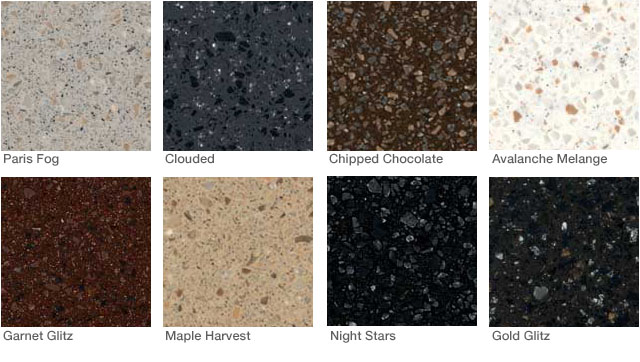

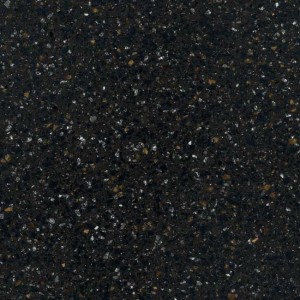

Also a composite, granite sinks are molded using ground up quartz pieces, quartz dust and acrylic resins and is the same color throughout. Similar to solid surface sinks, granite can also discolor with extended use. Although you can scour the surface and remove minor stains, excessive abrasion can lead to non-removable scratches.

Granite composite sinks are offered in a wide range of color options, with unique design features. This allows you to choose from a wide range of color contrasts, grains and patterns.

Cast Iron (Porcelain Enamel) Sinks

Cast iron sinks have a glass (also called porcelain enamel) surface, which is applied to the cast iron or steel basin and then fired at high temperatures. The glass color layer sits on top of the cast iron or steel. This glass layer is offered in a wide range of colors—such as black, brown, blue, gray, red and white, etc—based on the manufacturer’s options. It’s also important to note, the porcelain enamel surface can scratch and chip, which is non-repairable.

Stainless Steel Sinks

Stainless is made from different thicknesses of stainless steel (usually 18 gauge but can range from 16 to 23 gauge) Remember, the lower the gauge (thickness), the more durable the sink will be. Scratches can be removed or masked by using abrasives such as sand paper or steel wool. Always be mindful to go “with the grain.” All previous styles (solid surface, granite and cast iron) can chip, whereas stainless will dent permanently.

In general, stainless steel is a rugged, durable material. And, when it comes to antiseptic properties, stainless steel can also meet NSF 51 certification.

Top Mount (Drop-In) or Undermount?

Ease of Use – Top mounted sinks create a lip or edge, which prevents the easy sweeping of countertop debris into the sink while undermounted do not. Installing a top mounted sink will require caulking around the edge between the lip of the sink and the countertop. This prevents water from running under the rim.

Food Safety and Hygiene – Because of the caulking requirement, top mounted sinks provide a location for bacteria and mold to reside. Undermounted sinks also produce a seam that needs to be caulked and cleaned regularly.

Undermount Sinks – Standard or Seamless?

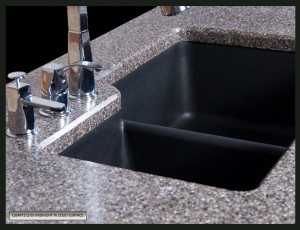

There are two types of undermount sinks—seamless, and one where the edge of the countertop extends beyond the inner edge of the sink, creating a visible joint.

In the typical undermount installation where the seam is visible, the sink can be glued or mechanically fastened under the countertop or both. The weight of the sink will dictate the method of installation, based upon the manufacturers recommendation. The joint between the top and bowl (on the sink bowl side) is typically sealed with silicone or caulk. Keep in mind that this area will need to be routinely cleaned to prevent the growth of bacteria and mold.

A seamless undermount is where the bond between the sink and the countertop is completed using an acrylic-based adhesive that hardens into a non-porous surface. The area of the seam is then routed and sanded so the countertop surface flows together with the sink surface. When the countertop and sink are the same color this joint is virtually invisible.

Solid surface and Karran stainless steel sinks can both be undermounted seamlessly. All types (granite and cast iron included) can all be undermounted in a non-seamless fashion.

Ease of Use & Hygiene – Seamless undermount sinks are easier to maintain and keep the most hygienic since there is not a caulk line to trap debris, bacteria and mold. This is an important consideration for sinks being placed in food preparation areas, dental and medical offices and other areas where an antiseptic environment is desired.

Learn how to install the various types of sinks in our Countertop Fundamentals instructional guides. Sinks, sink adhesives, mounting kits and other sink accessories can all be purchased at SolidSurface.com.